Tool to assess companies’ energy footprint and efficiency strategies

TerrAria prepares energy diagnoses for entities obligated under Legislative Decree 102/2014, as well as for voluntary entities. Large companies and energy-intensive businesses are required to prepare their energy diagnosis every 4 years, starting with the first deadline set for December 5, 2015, in compliance with Legislative Decree 102/2014, which implements the Energy Efficiency Directive 2012/27/EU. The energy diagnosis is an important tool for the company to know its energy footprint and to evaluate efficiency actions. In fact, the energy diagnosis is the tool through which to analyze the consumption profile, balance sheet and energy management of a company, in order to identify and quantify the opportunities for efficiency gains in the production processes involved and the general and auxiliary services supporting them, and finally, in the building-plant system in which the company performs its functions.

The main steps of the audit are:

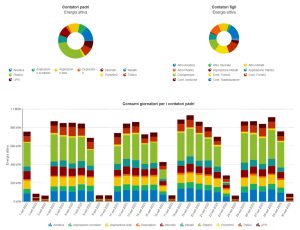

- Acquisition and processing of consumption data: energy consumption monitored by electric meters and gas meters;

- calculation of energy performance indicators from production data with the highest level of detail available;

- Inspection of the production site, including verification of the data and characteristics (powers, efficiency, hours of use …) of the main machinery;

- Analysis of the information collected and identification of any needs for further study;

- Discussion with the company on the pre-feasibility of possible energy efficiency measures;

- Preparation of the diagnosis report, in accordance with the provisions of Legislative Decree 102/2014.

To date, TerrAria has prepared more than 50 energy diagnoses, making use of ERGapp, a Web application developed in-house and delivered via Browser as a service accessible from any device (pc, tablet, smartphone) that is able to monitor and analyze energy consumption in real time, reconstruct the historical consumption series, visualize power quality parameters, analyze the company’s EnPIs (Energy Performance Indicators) and KPIs (Key Performance Indicators), and simulate the savings achievable from each energy efficiency intervention identified.